What is Liquid Penetrant Test?

Liquid Penetrant Test (LPT), also known as Dye Penetrant Inspection, plays a crucial role in ensuring the safety and reliability of components in industries where defects can lead to serious failures. This article will guide you through how this method works, highlighting its significance in discovering surface-breaking flaws.

Liquid Penetrant Test is a non-destructive method that helps identify defects on the surfaces of non-porous materials. Industries widely apply this technique to materials such as metals, plastics, and ceramics to ensure product integrity.

How Liquid Penetrant Test Works

Step 1: Preparing the Surface Properly preparing the surface is crucial for the success of Liquid Penetrant Testing. First, clean the material’s surface thoroughly to remove any contaminants like oil, dirt, or coatings that could hinder the penetrant’s ability to seep into defects.

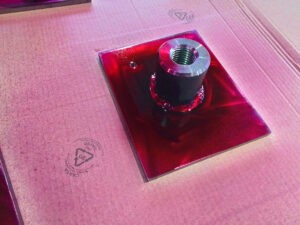

Step 2: Applying the Penetrant Next, apply a visible or fluorescent dye to the surface. Allow this dye to dwell on the surface for a specified period, giving it time to penetrate any surface-breaking defects due to capillary action.

Step 3: Removing Excess Penetrant After the dwell time, carefully remove any excess penetrant from the surface. It’s vital to do this step meticulously to avoid washing the dye out of the defects.

Step 4: Applying the Developer Then, apply a developer to draw out the penetrant from the defects to the surface, where it becomes visible. The developer helps to create a stark contrast that makes the inspection process easier.

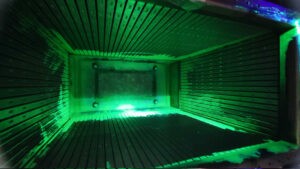

Step 5: Inspecting the Component Finally, inspect the component under appropriate lighting conditions. For fluorescent dyes, use a UV lamp. Any defects will appear as bright, vivid indications against the light background of the developer.

Applications of Liquid Penetrant Test

Liquid Penetrant Test is indispensable in many sectors, including aerospace, construction, manufacturing, and energy. This method is particularly effective for inspecting welds, castings, forgings, and machined parts that must withstand high stress and operate reliably.

Advantages of Liquid Penetrant Test

Liquid Penetrant Test is sensitive to small defects, making it an invaluable tool in the quality assurance process. Additionally, it is simple and economical, requiring minimal equipment. This method is also versatile, suitable for a wide range of materials.

Key Considerations

Despite its many benefits, Liquid Penetrant Test only detects surface-breaking defects and is not suitable for porous materials. Also, handling and disposing of chemicals used in the process requires careful consideration to minimize environmental impact.

Conclusion

Liquid Penetrant Test is an essential practice for maintaining high safety and quality standards in manufacturing and construction. By applying these methods, professionals can effectively prevent potential failures and ensure that products perform as expected.

Contact Us

For expert Liquid Penetrant Test services or more information on how LPT can be integrated into your quality assurance processes, contact SMART Consulting and Inspection. Our certified NDT professionals are ready to assist with all your inspection needs.

Pingback: Essential Guide to NDT Techniques & ISO 9712 Standards -