Corrosion is a significant threat to the structural integrity of pipelines transporting gas and liquids, potentially leading to leaks, ruptures, and substantial financial losses. Cathodic protection (CP) is a sophisticated and effective electrochemical technique for mitigating corrosion, thereby ensuring the longevity and reliability of these critical infrastructures.

Electrochemical Mechanism of Corrosion

Corrosion involves the deterioration of metals through an electrochemical process, where the metal serves as an anode, losing electrons and undergoing oxidation. This electrochemical reaction can be represented as:

Cathodic protection mitigates this process by converting the protected metal surface into the cathode of an electrochemical cell, thus preventing it from oxidizing.

Cathodic Protection Systems

There are two primary CP systems: Galvanic Anode Cathodic Protection (GACP) and Impressed Current Cathodic Protection (ICCP).

Galvanic Anode Cathodic Protection (GACP)

GACP employs sacrificial anodes composed of more electrochemically active metals, such as zinc, magnesium, or aluminum, which corrode in preference to the protected structure.

Technical Specifications:

- Anode Material Selection: The choice of anode material is based on the electrochemical series and the specific environmental conditions (e.g., soil resistivity, salinity). Magnesium anodes are preferred in high-resistivity soils, while zinc and aluminum are suitable for marine environments.

- Current Output: Anode current output is calculated using Faraday’s Law, taking into account the anode mass, electrochemical equivalent, and efficiency.

- Design and Placement: Optimal placement of sacrificial anodes ensures uniform current distribution. Advanced modeling techniques, such as Boundary Element Method (BEM) simulations, aid in designing effective GACP systems.

- Maintenance: Anode consumption rates must be monitored, with periodic replacement required based on depletion rates to maintain protection levels.

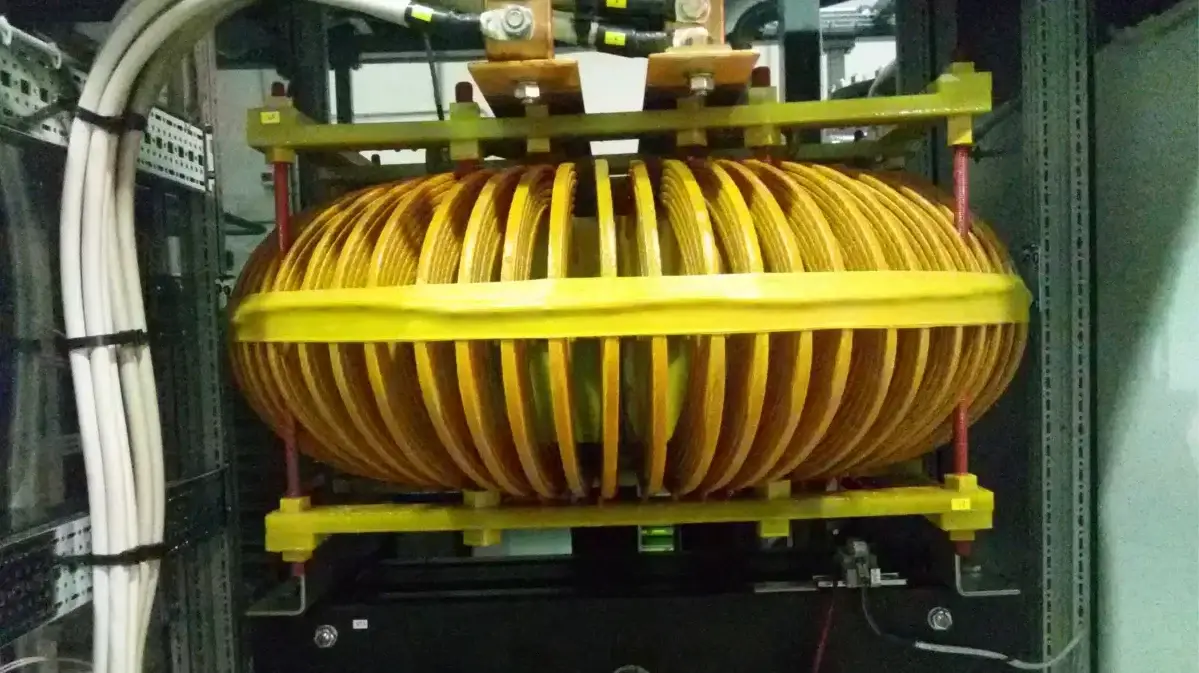

Impressed Current Cathodic Protection (ICCP)

ICCP systems utilize an external DC power source to supply a controlled current to the protected structure. Inert anodes, such as mixed metal oxide (MMO), graphite, or platinum-coated titanium, are deployed in these systems.

Technical Specifications:

- Power Supply: A transformer-rectifier unit converts AC to DC, allowing precise control of the protective current.

- Anode Materials: Inert anodes are selected for their high current density capacity, electrochemical stability, and environmental compatibility.

- System Design: ICCP system design requires a comprehensive understanding of current distribution, structure geometry, and environmental factors. Standards such as NACE SP0169 provide guidelines for determining appropriate current densities.

- Monitoring: Regular monitoring of potential and current distribution using reference electrodes (e.g., Cu/CuSO4, Ag/AgCl) is crucial for maintaining system effectiveness. Remote monitoring systems (RMS) and data logging enhance operational efficiency.

Monitoring and Maintenance

Continuous monitoring is essential for the effective functioning of CP systems. Techniques include potential measurements using reference electrodes (e.g., copper/copper sulfate, silver/silver chloride) to ensure the structure remains at a sufficiently negative potential to prevent corrosion.

Advanced Monitoring Techniques:

- Remote Monitoring Systems (RMS): Utilize data loggers and telemetry to provide real-time status updates and alerts.

- Electrochemical Noise Analysis (ENA): Offers insights into corrosion rates and the effectiveness of CP systems by analyzing the noise generated by electrochemical reactions.

Potential Failure Indicators and Diagnostics

Understanding potential failure modes and diagnosing issues promptly is critical for the integrity of CP systems.

- Power Supply Failures: A sudden drop in the protective current or voltage can indicate a failure in the rectifier unit. Regular inspection and testing of the power supply, along with monitoring output levels, can help identify issues early. RMS can also alert operators to fluctuations or outages.

- Monolithic Isolation Joint (MIJ) Failures: A compromised MIJ may result in stray currents leading to unexpected corrosion in isolated sections. This can be detected by observing unexpected potential shifts or through direct inspection of the MIJs for physical damage.

- Anode Depletion: In GACP systems, if anodes are significantly consumed without timely replacement, the protection current may drop below effective levels. Visual inspections and regular monitoring of current output can help detect anode depletion.

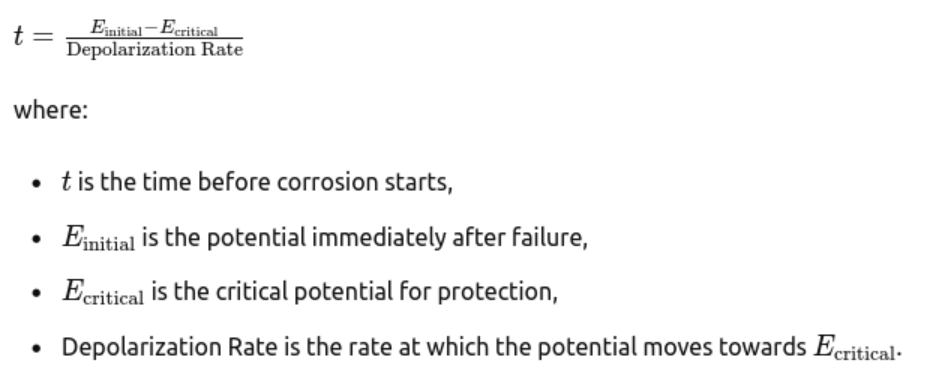

Calculating Time Before Corrosion Onset

To calculate the time before corrosion initiates following a component failure, engineers can use the following approach:

- Determine the Critical Potential: Identify the potential at which the structure is protected (typically -850 mV vs Cu/CuSO4 for steel).

- Monitor the Depolarization Rate: After a failure, measure the rate at which the structure’s potential depolarizes towards the critical potential.

- Calculate Time to Reach Critical Potential: Using the depolarization rate, estimate the time it will take for the potential to reach a level where corrosion is no longer prevented.

Role of Monolithic Isolation Joints (MIJs)

Monolithic Isolation Joints (MIJs) are integral to CP systems, providing electrical isolation between different pipeline sections to prevent stray current corrosion. MIJs are essential for maintaining the integrity of CP systems by ensuring that protective currents are confined to intended areas. Proper design and placement of MIJs are critical, involving considerations such as dielectric strength, mechanical robustness, and environmental compatibility.

Benefits of Cathodic Protection

- Extended Lifespan: CP significantly extends the service life of pipelines by preventing corrosion-induced deterioration.

- Cost Efficiency: Reduces the need for frequent maintenance and repairs, leading to long-term cost savings.

- Environmental Protection: Minimizes the risk of leaks and ruptures, thereby protecting the environment from hazardous spills.

- Operational Reliability: Ensures the safe and continuous operation of gas and liquid transportation systems.

Industry Applications

Cathodic protection is widely used across various industries:

- Oil and Gas: Protects both onshore and offshore pipelines from aggressive environmental conditions.

- Water Systems: Maintains the integrity of water distribution and sewage systems.

- Marine Structures: Safeguards vessels, offshore platforms, and harbor infrastructure.

- Underground Storage: Prevents corrosion in tanks used for storing fuels and chemicals.

Real-World Impact

The implementation of CP systems has demonstrated significant benefits across industries. In the oil and gas sector, CP has prevented pipeline failures that could lead to catastrophic spills and environmental disasters. In marine environments, CP systems ensure the longevity and reliability of vessels and offshore structures, thereby reducing maintenance costs and operational downtime.

European Standards and Italian Best Practices

Cathodic protection systems must comply with several European standards to ensure their efficacy and safety. Key standards include:

- EN 12954: “Cathodic Protection of Buried or Immersed Metallic Structures – General Principles and Application for Pipelines”

- EN 13636: “Cathodic Protection of Buried Metallic Tanks and Related Piping”

- EN ISO 15589-1: “Petroleum and Natural Gas Industries – Cathodic Protection of Pipeline Transportation Systems – On-land Pipelines”

- EN ISO 15589-2: “Petroleum and Natural Gas Industries – Cathodic Protection of Pipeline Transportation Systems – Offshore Pipelines”

For those operating in Italy, the Associazione per la Protezione dalle Corrosioni Elettrolitiche (APCE) provides valuable resources and guidelines for implementing and maintaining CP systems. APCE promotes best practices and the latest technological advancements in corrosion prevention and cathodic protection.

Alfa Smart System for MIJ Monitoring

In collaboration with Alfa Engineering, SMART Consulting has developed the Alfa Smart System, an innovative solution for the monitoring of Monolithic Isolation Joints (MIJs). This system integrates advanced sensors and real-time data analytics to provide continuous monitoring and diagnostic capabilities. Key features include:

- Real-Time Monitoring: Continuous data acquisition on the electrical isolation performance of MIJs.

- Predictive Maintenance: Advanced algorithms to predict potential failures and schedule maintenance proactively.

- Data Analytics: Comprehensive analysis and reporting to ensure the integrity of the pipeline system.

The Alfa Smart System enhances the reliability and efficiency of cathodic protection systems, ensuring optimal performance and extended lifespan of critical infrastructure. For more detailed information about this system, please visit the Alfa Smart System page.

Conclusion

Cathodic protection is a critical technique for maintaining the structural integrity and safety of pipelines transporting gas and liquids. By employing advanced GACP and ICCP systems, industries can effectively combat corrosion, ensuring long-term operational efficiency and environmental safety. Embracing CP technology is essential for the sustainability and economic viability of critical infrastructure.

Contact Us

For comprehensive information on cathodic protection and tailored solutions, contact SMART Consulting & Inspection. Our experts are ready to assist you in implementing the best corrosion prevention strategies for your infrastructure needs. For Italian stakeholders, additional resources and support can be found through the Associazione per la Protezione dalle Corrosioni Elettrolitiche (APCE).